To make this easier you d start with your 6061 material in the soft t 0 state.

Bending aluminum sheet 3 16.

Learn how to bend sheet metal so you.

The largest angle is only 40 degrees.

Place the fracture line over the edge of a table and bend the overhang slightly downwards.

Easily clamps or mounts to workbench.

With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet.

Makes bends to 90º.

In the annealed condition it can be used for bending since the difference between yield and tensile strength is 10 ksi and elongation is up to 18.

Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal.

Let s consider a challenging job.

Part gets bent from 180 degrees to 140 degrees i just tried this on a small sheet metal type brake but it was trying to pry open the brake.

This weakens the aluminium and creates a fracture line.

Longitudinal bending or bending with the material grain increases the required minimum inside radius of the bend.

Minimum inside bend radius for steel aluminum and stainless you will find a variety of minimum bend radii to thickness ratios and you will need to research these values in data provided by your material supplier.

You d probably air bend by using a 3 0 in.

I have a piece of 8 5 wide 3 16 thick 5052 aluminium that needs several bends.

The brake is compact and lightweight yet sturdy enough for professional production runs.

This is a highly technical and potentially dangerous process best left to a professional metalworker.

Heavy gauge aluminum bars or rods must be heat bent using an acetylene torch and vice.

Die opening with a relieved profile.

Bends metal up to 18 in.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

When moving up to t4 and t6 tempers however bending ability tends to decrease.

Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one.

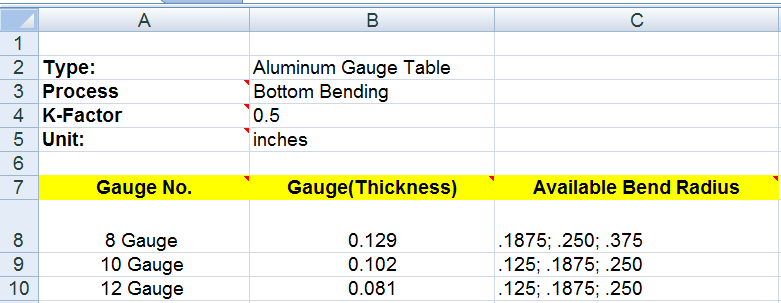

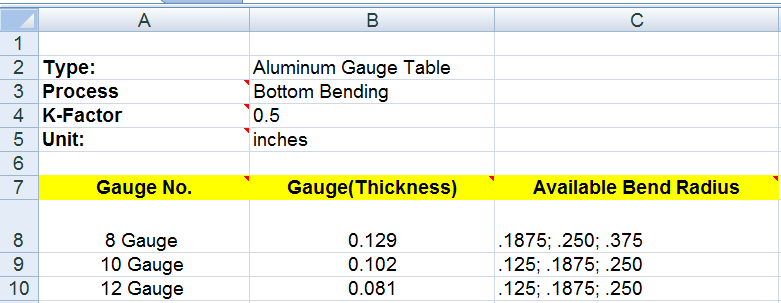

Material bend radii and minimum bend size charts please note.

Say you re bending 0 25 in thick 6061 t6 aluminum to a 100 degree external angle 80 degree internal angle.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Handles material as thick as 16 gauge.

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.